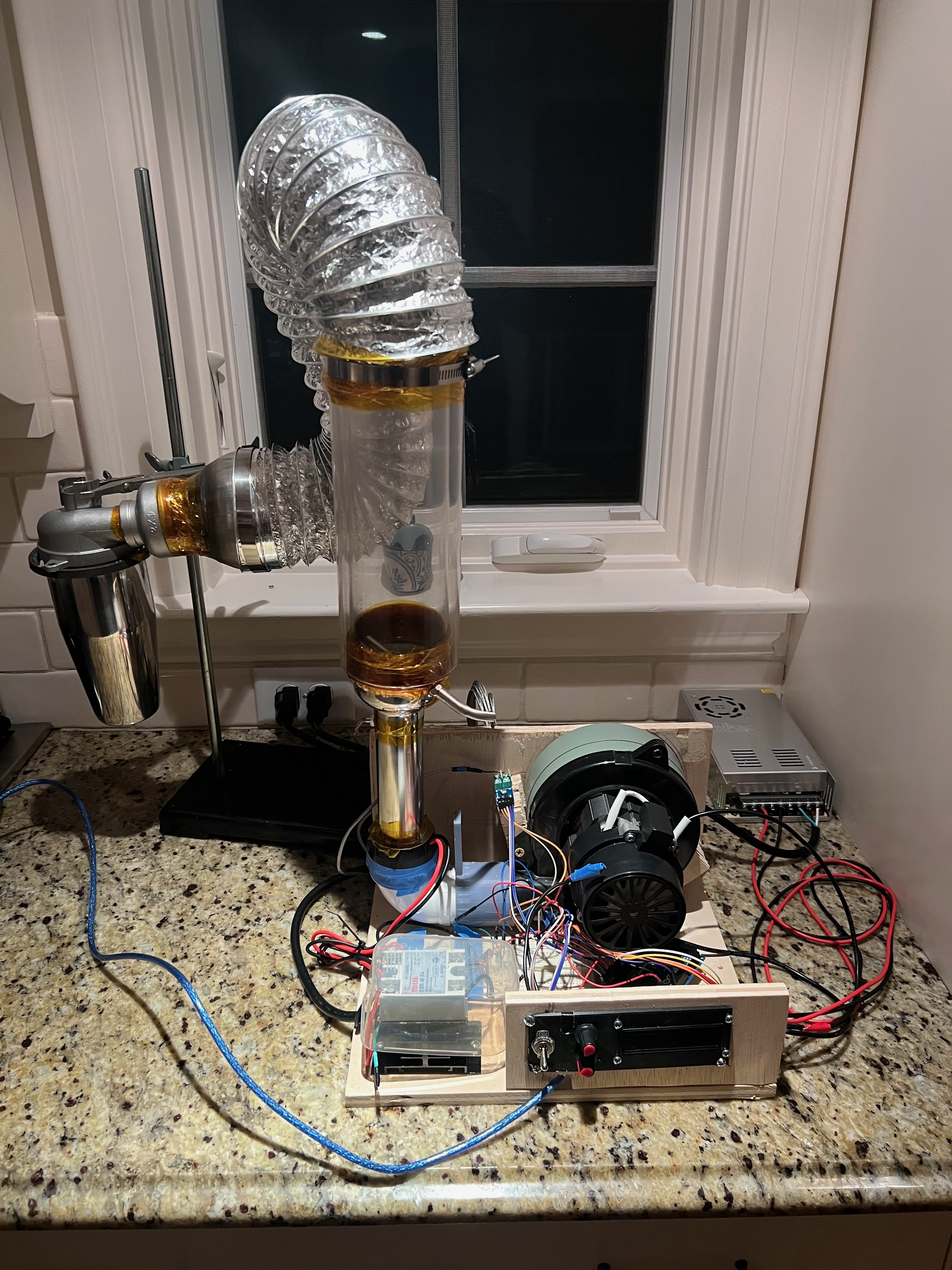

Custom-Built Fluid Bed Coffee Roaster

Description:

To roast good coffee, simply put, you need to evenly roast the beans, and be able to repeat temperature profiles consistently to experiment and iterate. To solve this problem while not spending thousands of dollars, I designed and built a custom fluid-bed coffee roaster. Traditional roasting methods can be inconsistent, and I wanted to create a platform that would allow both experimentation and replication of roasts. The system uses a high-powered blower to fluidize the beans, eliminating the need for mechanical agitation and ensuring even heating. A ceramic air heating element provides adjustable heat, while the entire system is monitored and controlled through an Arduino Mega connected to Artisan coffee roasting software via MODBUS serial communication. Artisan runs a PID control loop that adjusts motor speed and heating element power in real time, following a user-defined temperature profile. Two thermocouples measure both bean temperature and environmental temperature, allowing precise control and analysis.

I began by researching existing fluid bed designs, online blogs, and video demonstrations. I modeled components in Onshape, designing parts for 3D printing and planning clearances for heat-sensitive materials. The roasting chamber combines stainless steel and borosilicate glass, and the exhaust system incorporates a cyclone separator to remove chaff while preserving airflow. Testing involved iterative tuning of the PID parameters, adjusting probe placement, and refining both hardware and software to ensure safety and consistency. I implemented features such as automatic shutdown if the fan fails and maximum temperature limits. Future additions include audio detection of coffee cracks, which could allow predictive modeling of roast stages.

The most exciting aspect is the combination of electronics, design, and data analysis. By integrating the roaster with Artisan, I can record roasts, replicate profiles, and experiment with new parameters, making the project both a tool and a research platform. Challenges included heating element capacity, probe placement, and sufficient bean mass agitation. Each issue required troubleshooting and adaptation, which strengthened my practical engineering skills. Ultimately, the project succeeded in providing a consistent, controllable, and experimental platform for coffee roasting, and it remains a foundation for further experiments in both roasting science and hardware design.

Tools:

All the tools that I used in this project:

Arduino C++ Python Onshape CAD 3D printing (PLA) MODBUS Artisan